Shipment and transport require a great deal of strategic planning. The logistics behind transportation become even more specialized when dealing with extremely large or abnormally shaped cargo. Logistics managers have to plan for special permits and regulations, added costs, and unique container types and safety measures.

This out of gauge cargo (OOG) guide for logistics managers explores the world of managing OOG cargo, featuring examples of OOG cargo and practical solutions and relative services for this cargo type.

What Is Out of Gauge Cargo?

Out of gauge cargo can also be called an abnormally shaped indivisible load. It refers to freight that is too large for traditional shipping containers — oversized or oddly shaped cargo that exceeds the dimensions of a standard shipping container. For comparison, conventional cargo fits the dimensions of traditional shipping containers — that is, either 20 feet or 40 feet in length, 8 feet in width, and 8.5 feet in height.

Shipping OOG cargo is often necessary, but it requires more planning, extra costs, extra equipment for loading and offloading, and an added workforce to accommodate the abnormal load.

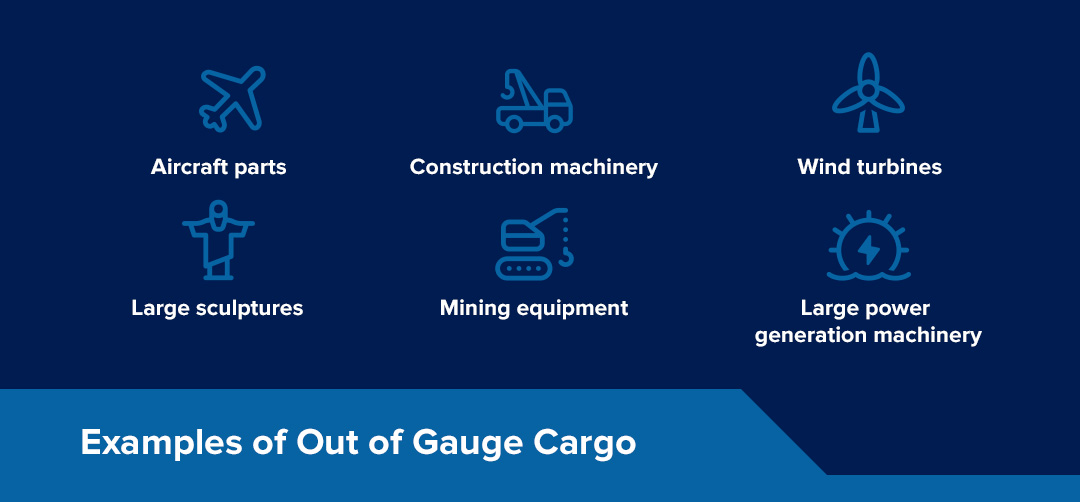

Examples of Out of Gauge Cargo

A wide range of industries rely on OOG solutions, from transportation and construction to industrial sectors. These industries rely on quickly and safely transporting and receiving various kinds of oddly shaped cargo. Examples of OOG cargo include:

- Aircraft parts

- Construction machinery

- Wind turbines

- Large sculptures

- Mining equipment

- Large power generation machinery

Out of Gauge Cargo Container Types

With traditional cargo, workers typically organize the cargo into standard shipping containers and load the containers onto vessels using forklifts or cranes. The process is different for OOG cargo, meaning operators have to find unique out of gauge container and transport solutions, including:

- Open-top and flat rack containers: Depending on the cargo, top or side loading may be the best choice, and open-top and flat rack containers are two designs that suit these loading solutions. An open-top container may have a removable roof or no roof at all. Flat rack containers have collapsible ends and no sides.

- Modifying traditional containers: Though not a particularly common solution, there may be times when modifying traditional containers is the way to accommodate oddly shaped OOG freight — for example, creating openings for components that jut out. This option adds extra logistics to the project, as modifications will need special approval for safety and quality assurance.

- Roll-on, roll-off (RORO): RORO vessels are specially designed ships that carry wheeled cargo like cars, buses, motorcycles and trailers. Dock workers either drive the vehicles onto the ship or use platform vehicles to load or offload the cargo. RORO vessels have adjustable decks and extendable ramps to make loading and offloading as practical as possible.

- Aircraft and vessel charters: Aircraft and vessel charters are ideal when there is a considerable amount of non-containable cargo to move.

How to Ship Out of Gauge Cargo

Shipping OOG cargo is a detailed process that relies on a wealth of expertise in different areas. If you are anticipating shipping OOG freight, the process will resemble the following steps.

- Outline: Get a detailed outline of what you will be shipping. You should know the cargo’s dimensions, center of gravity and lifting points to protect the cargo and staff as they load and offload. If you can, get a technical diagram the loadmaster can use to confirm these elements.

- Requirements: Ask if there are any extra requirements for safely hauling, lifting and securing the load.

- Planning: An operational cargo specialist can start planning the load’s shipment with custom solutions in mind. The plan should include every point of operation from collection to arrival. For example, the specialist will consider which equipment and transport is needed to collect the load from the origin facility and haul it to a loading zone. Another important consideration is how many trips to plan for so as not to overload the transport.

- Documentation: Once a plan is in place and the logistics manager gets approval, they will ensure all the required documents and permits are in order to transport special cargo.

- Shipping: Finally, you will work with the team to load and ship the OOG cargo according to your plan.

Ensuring Safety and Compliance in Out of Gauge Cargo Transport

As with any form of shipping, compliance and liability are top considerations. OOG cargo is its own specialized area of transport, and you should take extra care to ensure best practices for loading, securing and unloading OOG cargo. You can mitigate risks by ensuring the following areas are in order:

- Dimensions: Always have precise dimensions from the manufacturer. Because lifting solutions, vessel types and trailer choices are all affected by the cargo’s shape and dimension, even the slightest discrepancies can lead to damaged goods, safety compromises, delays and other liability concerns.

- Permits: Permits are a big part of logistics. For OOG cargo, you need special permits from the Department of Transport or other appropriate authorities for transporting the cargo on roads. Under exceptional circumstances, you may even need to contact local authorities to plan a safe route.

- Documentation: All international shipments are subject to customs and border protection measurements. The good news is most documentation for OOG cargo is the same as for general cargo, including insurance documents and bills of landing.

At the same time, you want to ensure your team is prepared to handle OOG cargo transport. These shipments require special attention, just as they require special shipping methods. For example:

- Keep loading areas clean and free of obstacles.

- Train everyone to prioritize safety according to their work responsibilities.

- Ensure workers wear personal protective equipment at all times.

- Secure cargo with proper tie-downs and lashings to help ensure protection.

Keeping safety and compliance front of mind is essential for successful OOG cargo transport, and you can boost your chances of success when you work with the right global logistics provider.

Specialized Out of Gauge Cargo Logistics Solutions With Emo Trans, Inc.

Handling OOG shipments is an involved process. It requires expertise in logistics, shipping and handling to ensure compliance and the seamless transportation of your cargo. As a result, partnering with the right transport company can make a considerable difference in the efficiency and safety of transporting your OOG goods.

At EMO Trans, we offer premium global transportation services. With network offices in 120 nations spanning six continents, you can rely on us as a leader in logistics services, including specialized OOG cargo logistics solutions that help you meet your customers’ expectations. No matter your needs, we can work with you to establish an optimized, streamlined approach for shipping OOG cargo.

Contact our knowledgeable team today to discuss our custom services or request a quote.